Hydrogen Blending

SMART IAC's award-winning project tackles carbon emissions

In 2020, industries contributed a staggering 24 percent of the United States' carbon dioxide emissions. To combat this alarming statistic, the U.S. Department of Energy (DOE) unveiled an ambitious strategy to combat this statistic, setting the stage for an era of change.

The DOE's commitment to reducing carbon emissions was underscored in 2022 when it awarded UC Irvine one of just eight prestigious student research awards. This recognition solidified UC Irvine's role in supporting the nation's decarbonization goals.

SMART IAC's goal is to develop software tools that analyze operating conditions in manufacturing companies to optimize hydrogen blending.

Hydrogen, the most abundant element on Earth, has garnered attention as a potential game-changer in the quest for cleaner energy.

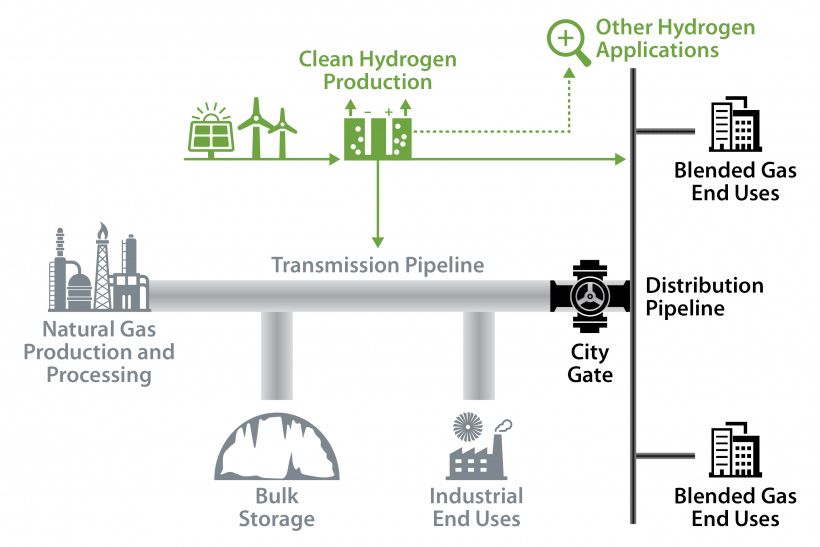

The versatility of hydrogen extends across various sectors. It can power cars, energize industries and serve as a linchpin in the renewable energy landscape. Production methods include harnessing wind, solar and biomass resources. This is where the concept of hydrogen blending enters the picture.

Hydrogen blending entails the integration of hydrogen with natural gas, offering a path to generating heat and power with significantly reduced emissions compared to using natural gas in isolation. However, challenges such as storage and production costs need to be addressed for widespread adoption.

SMART IAC's Innovative Approach

SMART IAC has set an ambitious goal to spearhead the hydrogen blending revolution. Their vision involves developing state-of-the-art software tools capable of analyzing operational conditions within manufacturing companies, ultimately optimizing hydrogen blending.

At the core of SMART IAC's mission is their software model. This digital tool seamlessly processes input parameters such as operating pressure, temperatures and pipeline dimensions. Through complex calculations, it forecasts future reductions in emissions and assesses financial implications, ultimately identifying the most ideal scenario for each facility.

As industries worldwide grapple with the pressing need to decarbonize, SMART IAC's award-winning project promises to revolutionize energy practices. With hydrogen blending on the horizon, the path to reduced carbon emissions appears clearer, one algorithm at a time. SMART IAC's innovation isn't just a beacon of hope; it's a tangible step towards a sustainable future.

SMART IAC OVERVIEW

In 2021, UC Irvine received nearly $2.25 million of a $60 million investment by the U.S. Department of Energy to assist small- and medium-sized manufacturers in reducing their greenhouse gas emissions and lowering energy costs, while training the next generation of energy-efficiency workers.

The Sustainable Manufacturing Alliance for Research and Training Industrial Assessment Center (SMART IAC), housed at UCI’s California Institute for Telecommunications and Information Technology (CALIT2), operates the center with two satellite centers at CSUN and Cypress College. IACs provide small- and medium-sized manufacturers with assessments and recommendations on energy efficiency, productivity improvement, sustainability and competitiveness as well as measure the impacts of these recommendations on reducing greenhouse gas emissions.

“While large, sophisticated companies like SpaceX dominate the public’s perception of manufacturing in Southern California, it is the manufacturers with fewer than 50 employees that produce most of the innovation, output and employment,” said G.P. Li, project PI and UCI CALIT2 director. “I am proud that UCI has been selected to help small- and medium-sized manufacturers across America lower their energy costs and reduce greenhouse gas emissions while remaining globally competitive. This is further acknowledgment of UCI’s commitment to clean energy. By harnessing the talent of our brightest minds, we can take on the energy, environmental and economic challenges of tomorrow.

ABOUT US

Our SMART IAC provides no-cost energy consulting services to small- and medium-sized manufacturers within 150 miles of UC Irvine (Orange, Ventura, Imperial and Riverside counties.) We have expanded our program to provide commercial building assessments, too.

Our assessments typically require one day on site in your facility and we typically identify 10-20% energy and productivity savings.

As part of our services, we will deliver a detailed, professional report outlining several ways that your facility can save energy and money. Our analysis includes detailed engineering and economic calculation of potential energy saving ideas. We typically only target recommendations that result in a 2-year financial payback for our clients.

__________________________

UC IRVINE CALIT2

featuring the SMART IAC

__________________________

Credits

Writer: Sharon Henry

Video: Natalie Tso

Editor: Shelly Nazarenus